|

THE BLUEPLANET BE3 ELECTRIC

|

|||

|

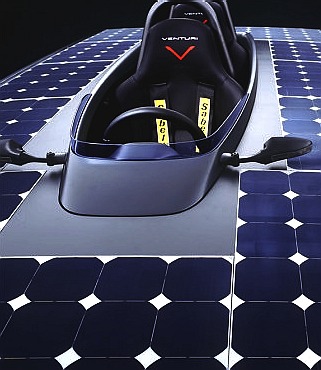

LEGENDARY DESIGN - The world's fastest electric car: 350mph + using energy from nature. Featuring built in battery cartridge exchange, charged using renewable solar energy. Sponsors were being sought for the 2016 season, but this project has been put on hold until 2018 at the earliest.

The BE3 is a truly innovative range extender for electric vehicles - and the attempt is solar powered. Yes, that's right, the BE3 high performance racing car is powered by energy from nature. How many 300 mph plus streamliners can claim that?

Between 2015-2016 the body was been lowered. elongated and narrowed. Whereas the BE2 had a forward driver position for maximum aerodynamic efficiency, the BE3 has a traditional drag streamliner arrangement, with the driver at the rear, faired into the tailfin. The Venturi Jamais Contente Buckeye Bullet team decided that their mid driver position made little difference to their aerodynamics, but they preferred the middle seating for driver comfort.

The Blueplanet team hoped to power this revolutionary car into the record books with an attempt on the British land speed record from as early as 2015. The Blueplanet team hope to break the 250mph barrier in the UK with the BE3's technology, then go on to the USA to attempt to break the 350mph barrier. It's a race between the Buckeye Bullet BB3 and the BE3, which begins at Pendine Sands. The UK record currently stands at 204 mph, set by Lord Drayson in June of 2013, driving his converted Lola LMP1.

It all began with a patent application for a 170 mph V6 petrol engined joystick car, which took the best part of 6 years to hand build. Soon after that Sussex (UK) based eco-innovator Nelson Kruschandl filed his second patent. This time he wanted to build an electric car that had a respectable range. The only way he could think of to achieve this, was to fit new batteries as quickly as possible, when the old ones were drained.

PROJECT BACKGROUND

The design team wanted this car to be as self-supporting as possible. Thus, the car had to have an integral mechanism to change batteries, and logically, the batteries would have to be one large cartridge. He designed and tested a fast pneumatic loading system based on two cylinders, one at each end of the vehicle. Later cars featured the same cartridge, but a flat electrically powered servo at each end of the vehicle. This system was successfully fitted into a road car, with cartridge exchange speeds of around a minute - faster than filling up with petrol.

The 'Blueplanet Ecostar' electric streamliner with built in battery cartridge refueling system. This is a model of the original concept from 2006. The proposed future (from 2018) car is now much lower and longer.

That is the concept behind the latest all green 'Eco' electric world challenger, a further development of two original LSR concept racing cars from 1993/5 and 1996/7 featuring battery cartridge exchange as a means of refueling the car after each flying mile run: the BE1 and BE2. The inventor was granted a patent for his original system and we are keeping the latest improvements a secret, to be able to apply for additional patent protection should funds be secured for this valuable social research. The BE2 is one of the most beautiful land speed record car to date, which the BE3 team hope to surpass with their latest curves.

Buckeye Bullet 2 BB2

The Blueplanet Ecostar is the only electric LSR vehicle to feature built in battery cartridge refueling. We believe that the Blueplanet Ecostar LSR has all the ingredients to set a blistering pace across sand and salt. It is 'possibly' the most powerful electric car in the world. Development of such a system for road cars ceased after the UK Department of Trade and Industry (Dti) formally advised that battery electric cars had limited prospects. Funding of such development is always a problem for innovators, and that body blow from 'Foresight' killed all thought of investment until the present call for proposals from the European Commission and now NineSigma.

The team believe that the future of motoring rests with the development of efficient electric vehicles, be they solar assisted, hybrid, battery or fuel cell. But all of these formats will benefit by battery cartridge exchange - which allows near instant refueling.

For 2014/16 the chassis has been redesigned to cope with more power and a new transmission. A package the designer hopes will propel the Blueplanet Ecostar™ into the international record books and could eventually break the 400 mph barrier. He says: "It would be a gigantic leap forward if we can get an electric vehicle to compete with its piston petrol powered rivals. The record book would then have gone full cycle, where the first land speed record was indeed electric."

Currently there is one US team to beat:-

Featuring a unique transmission and curvaceous styling, computer analysis reveals that in its current form the Blueplanet BE3 is capable of significantly exceeding 350 mph. The car is to be constructed in Sussex, England, aiming for a showing in 2012-13. However, John points out that we are still searching for a Prime Sponsor such as an energy company, motor, or solar panel manufacturer or both, without whom the attempts planned for 2013 and 2014 may not take place.

As and when the Blueplanet Ecostar breaks the 300 mph barrier and more, we hope this feat will underpin the aspirations of many Governments for efficient road going performance EV's, without having to worry about range.

Few people have so much hands on experience experimenting with battery cartridge exchange mechanisms. We are inviting motor manufacturers to consider working with our designer, not only to prototype (convert) a car from your existing range of vehicles to incorporate battery cartridge refueling, but also to prototype electric vehicle refueling forecourts - with Pay As You Drive (PAYD) intelligent battery support.

THE BLUEBIRD ELECTRIC BE1

The BE1 was one of the lightest electric land speed record racing cars ever built, weighing in at under 400lbs, without battery cartridge. The frame was so light it could be lifted above the designer's head with one hand. The frame was transported on the roof of a Volkswagen Baja.

DESIGNED FOR SPEED - The chassis of the BE1 is seen here lifted using one hand. This speaks volumes about the design. A stressed aluminium skin would complete the structure, with composite nose and tail fairings.

Being so light, the power to weight ratio was very high. Hence, acceleration was brisk and the rolling resistance low. The low frontal area meant that aerodynamic drag was also low. One of the basic design features is to concentrate loads across the axles. Many electric cars have the battery mass in the middle of the structure. By using a cartridge, loads are fed into the chassis nearer to the wheels, enabling the vehicle frame to be lighter. This car could have been lighter still by using carbon fiber and more aluminium.

The motor mass was also concentrated at the axles, reducing the length of the drivetrain and as with the cartridge design, the weight of the main frame.

The other secret to high performance is the ability to detach the battery cartridge quickly. For early LSR trials, lead-acid starter plates were used, removed from their casings to save mass. If development had continued, nickel metal hydride would have been the next format. Today that would be lithium polymer, or similar. No matter what the chemical composition of the energy store, the battery cartridge externally retains the same dimensions.

ROOF RACK - The chassis of the Bluebird-Electric 1 was so light that this VW Baja had no difficulty transporting it from Filching Manor Motor Museum, which is where the frame was made. The VW camper in the background is now under restoration for SeaVax and the Cleaner Oceans Foundation, for use as an event support vehicle during their Feed the World campaign.

This picture was taken inside one of the former chicken sheds at Filching Manor Motor Museum. The chassis is laid out with some of the early running components. The aluminium dashboard is visible, made of 1mm alloy sheet. Cars under construction rarely look like the finished item. But the clue to the final form is here.

Another weight saving feature is these two lightweight compressors. They were used to power the servo mechanism that loaded and unloaded the lightweight battery cartridge (two per pneumatic servo) in less then two minutes. The lift cycle could take less than 10 seconds using a combination storage system. Lowering was also very fast. The time consuming part was roll-on and roll-off, which can be significantly improved for production cars.

These are two of the aluminium frames for the cockpit canopy that weighed not much more than a kilogram when assembled.

The alloy canopy is painted in satin-matt black. The mounting is also made of aluminium, here seen pop-riveted to the GRP nose cone.

The BE1 was the subject of continuous development over its short operational life. Here it is seen with ordinary road wheels/tires used for transport purposes. The car sits adjacent to the CN7 at the National Motor Museum, Beaulieu. There is no tail fin at this stage. Later a tail fin was added then alloy wheels and finally (not in the picture below) racing motorcycle tyres.

The land speed record was raised again by White Lightning before the BE1 could b used for a timed event. Thus the BE2 came into being, a faster design with forward seating, as in the CN7 (Campbell/Norris7). The BE2 had a wider body, but enclosed wheels. It used a double cartridge to store energy for 300kW over a measured mile course. Once again, there was no such thing as lithium batteries in those days.

A presentation was given to the board (Bluebird Stores) at a meeting in London, when the Project Leader and Don Wales were interviewed by the BBC. Sir Terence Conran was the generous host.

The then project leader, Nelson Kruschandl (left), with Sir Terence (middle) and Don Wales (right). The BE2 model that the men are holding was made by an outside firm and was not in accordance with the plans (as per the buck and grp bodywork subsequently produced. Sir Terence is holding a die-cast model of an earlier Bluebird designed by Reid Railton and raced by Sir Malcolm Campbell in the 1930s.

The BE2 project leader is interviewed by the BBC with Don Wales in the background

Contact

the BE3 team, Leslie or Terry:

+44 (0) 1323 831727 +44 (0) 7842 607865

Intelligent Battery Support System

The beautiful lines of the BE3 were inspired by Reid Railton (pictured above left) and his designs for the Napier Lion and Rolls Royce engined Blue Bird LSR cars of the 1930s for Malcolm Campbell. The Blueplanet BE3 features instant battery recharging using the patent Bluebird™ cartridge exchange system under license from BMS. This LSR car is also solar assisted. She is designed for speeds in excess of 350mph using clean electricity - and what a spectacle she will make charging along historic venues such as Pendine Sands, Daytona Beach and the Bonneville Salt Flats. The blue bird legend continues.

LINKS

http://www.vietnamplus.vn/Home/Venturi-Jamais-Contente-2010

|

|||

|

This

website is Copyright © 2017 Bluebird Marine Systems. The

names Bluebird, Solar Navigator™,Blueplanet Ecostar BE3™, Utopia

Tristar™ and the blue bird in flight

|